EVAPORATORS

About This Project

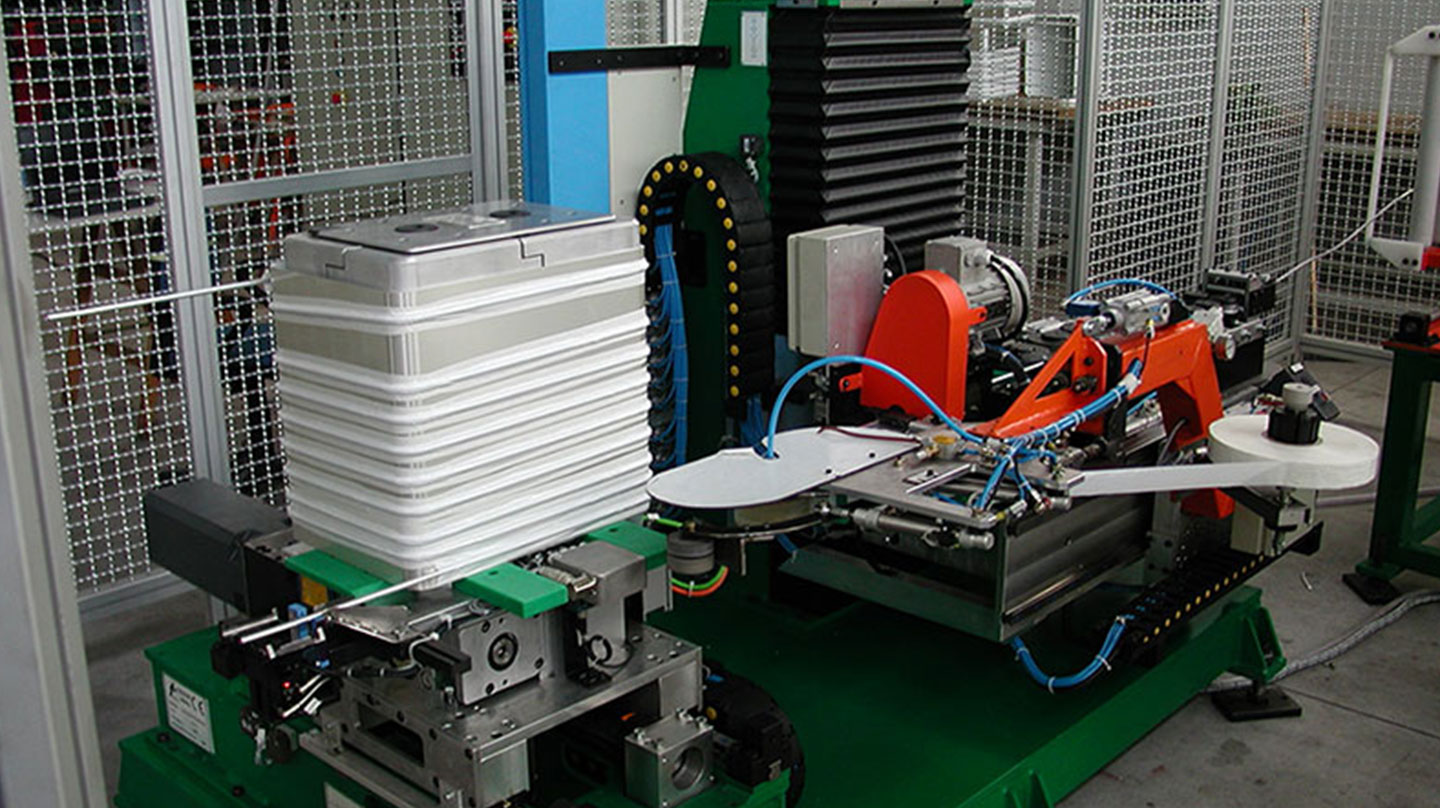

Self Group Comi TEAS designs and manufactures completely automatic and performing systems with the maximum degree of customization for the production of wrapped evaporators for refrogerators inner liner/cells or the application of off-line evaporators by gluing or other fixing technology, according to the multiple requests of our customers’ R & D divisions

SiamoWe are able to realize

- Evaporator winding stations on a thermoformed cell

- Aluminum cell forming stations and relative evaporator winding

- Evaporator bonding stations on a thermoformed cell

Features

The departure of our wound evaporator production lines is generally carried out by coils and includes straightening, cutting and wrapping. The shape of the pipe can be “D” rather than “O”, according to the project needs.

In the case of thermoformed cells, based on the target of thermal exchange efficiency required, Self Group Comi TEAS solutions can include the pre-coating of the inner liner trough an aluminium tape, the creation of a butyl conductive paste saddle between the pipe and the inner liner wall and the external protective covering of the pipe with plastic or aluminium tape.

The Self Group Comi TEAS technology guarantees the highest quality standards and ensures the absence of signs inside the inner liner or cell due to excessive winding on the corners of the tube.

The above is guaranteed by the presence of interpolated axes between pipe feed and cell rotation, resulting in the elimination of tension at the point of contact which is the main cause of aesthetic defects.

In terms of system configuration, the evaporator winding stations can be supplied as stand-alone with manual loading and unloading or integrated in automatic systems including terminal processing (tube ends expansion / reduction), as well as they can be supplied with automatic versions with expandable taps to be adapted to the various cell sizes.

With regard to the application of produced off-line evaporators, we can finally provide gluing solutions using hot melt (spray guns or coating) handled by gantry or robot.