Large Scale Additive Manufacturing

About This Project

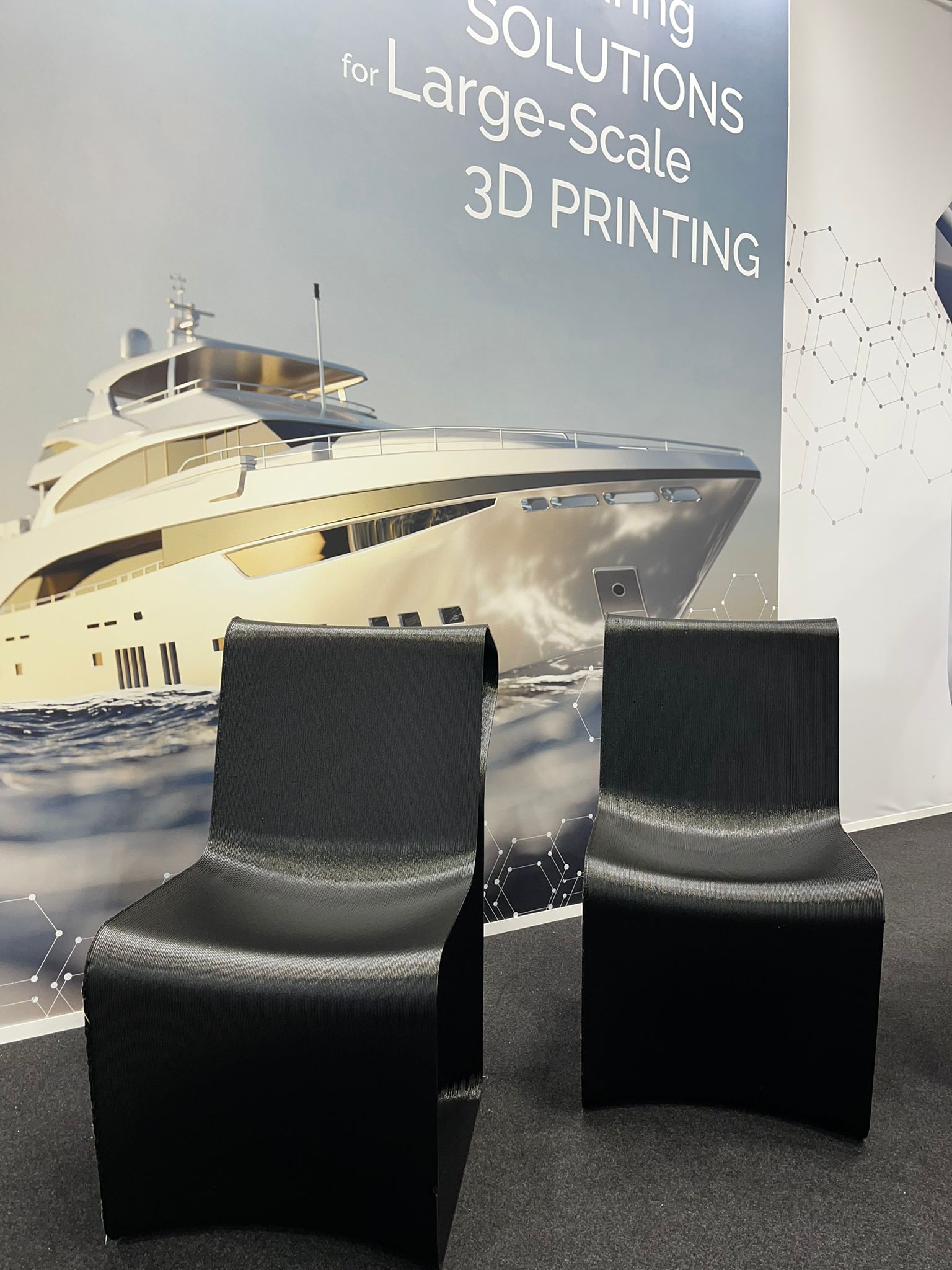

Additive manufacturing, also known as 3D printing, has revolutionized the manufacturing industry. It offers unprecedented freedom in design and the ability to produce complex geometries with remarkable precision. Our milling machines takes this technology to the next level, enabling rapid and cost-effective production of components. By incorporating large-scale additive manufacturing capabilities, we empower manufacturers to optimize their production processes and achieve superior results.

But that’s not all—they goes beyond additive manufacturing. With its cutter functionality, it provides a comprehensive solution for a wide range of manufacturing needs. Whether you require precise trimming, shaping, or finishing, the machine delivers outstanding performance. Experience firsthand how this versatile machine combines the best of both worlds, offering unparalleled flexibility and efficiency.

LARGE 3D PRINTING

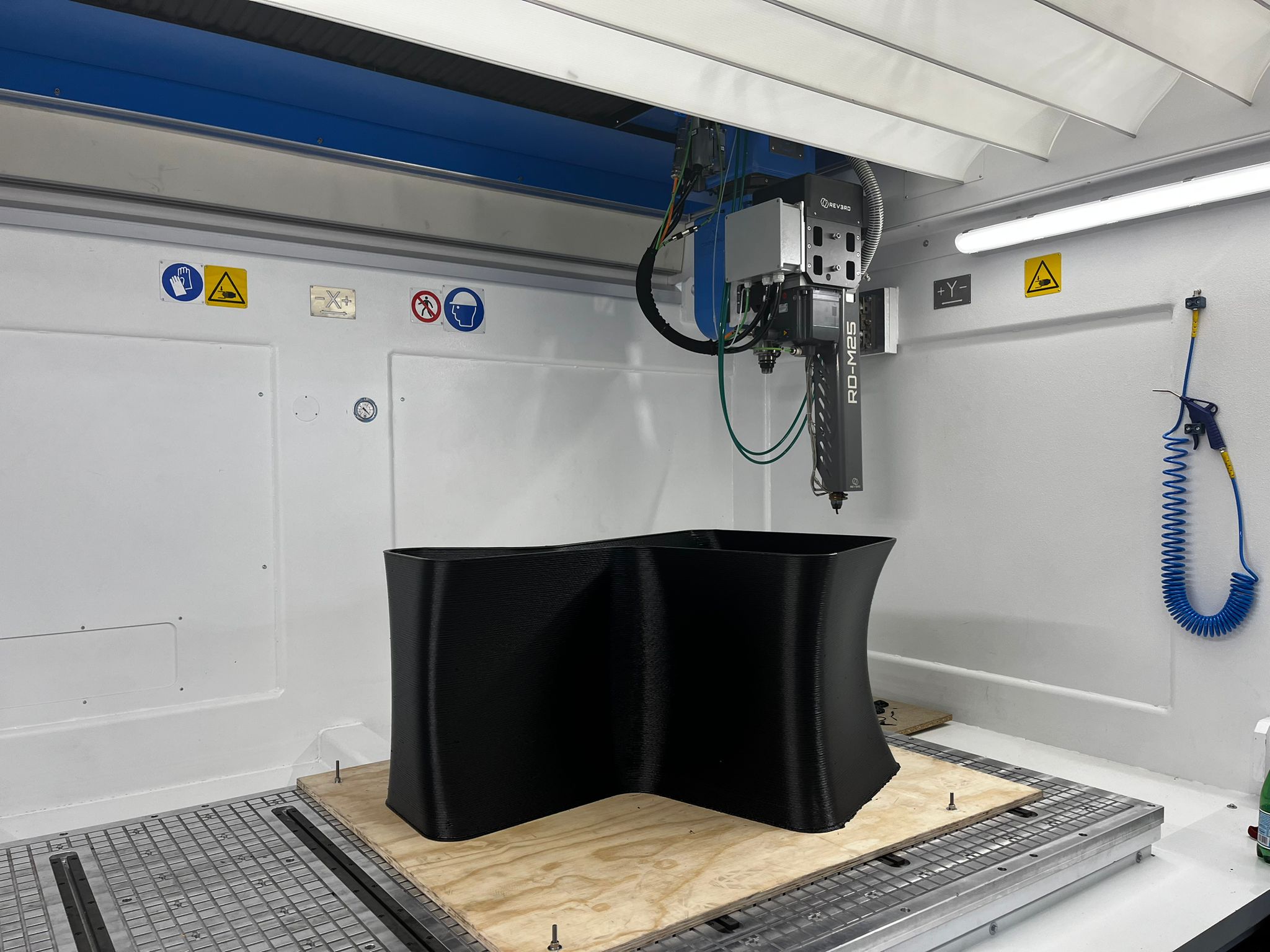

Thanks to the collaboration with the innovative tech startup REV3RD, a revolutionary extruder has been assembled. It’s able to produce large-scale 3D objects in aeronautical, automotive and construction fields.

One of the key advantages of the large-scale additive manufacturing is its lead time reduction. The entire process, from design to the production floor, can be achieved in significantly less time compared to conventional methods. This accelerated turnaround time provides manufacturers with a competitive edge, allowing them to bring products to market faster and respond swiftly to changing demands.

Furthermore, the additive manufacturing solution presents notable cost benefits. By employing this technology, companies can significantly reduce touch labor and minimize material waste, leading to substantial savings. This streamlined approach not only enhances the bottom line but also ensures sustainable practices, aligning with the growing emphasis on environmental responsibility within the manufacturing industry.

Innovative & Recycled materials

By leveraging this technology, the company provides a comprehensive tool manufacturing solution. The machines, paired exclusively with innovative and recycled materials, specialized in Large Scale Additive Manufacturing, offers to the client also a unique material developed specifically for advanced composite tooling applications. This innovative approach encompasses patent-protected processes and trademarked products for high-temperature and room-temperature applications.

Revolutionizing 3D Printing: Introducing the RD-M25 with Advanced Features

The world of 3D printing continues to evolve at a rapid pace, and REV3RD is at the forefront of this technological revolution. Their latest offering, the RD-M25, boasts an array of advanced features that redefine what is possible in the realm of pellet extruders. This next-generation machine is designed to deliver fast and cost-effective 3D printing, making it a game-changer in the industry.

TECHNICAL DATA

| Axes Strokes | Axes Speed | |

| X | 2.000 – 20.000 mm | 80 m/min |

| Y | 2.000 – 11.000 mm | 80 m/min |

| Z | 1.250 – 4.500 mm | 40 m/min |

| A(*) | +/- 120° | 40 m/min |

| C(*) | +/- 365° | 30 m/min |

NOTES: (*) Variable depending on the head type

SPINDLE FEATURES

| Power | 15-42 kW |

| Speed | 24.000 rpm |

EXTRUDER RD-M25 FOR ADDITIVE MANUFACTURING

| PARAMETER | VALUE |

| Max flow | 25 kg/h up to 200 kg/h |

| Available nozzle sizes | from 3.0 to 12.0 mm |

MATERIALS

The 3D printing process uses composite materials of various types:

– PA6 material

– PC material

– PET-G material

– Material PP+talc

– PUR material

– Glass Fiber

– Carbon Fiber

– Bio Based fibers