automotive

About This Project

Innovation in the production of special car fittings

PROBLEM

Adjusting standard cars to ambulances, vehicles used for the transport of people with disabilities, police cars, funeral vehicles requires the modification of the interior of side panels and doors, seats and footboards, designing and creating new solutions designed for their special use.

In addition there is the need to produce a relatively small number of pieces, thin in thickness, with the maximum production flexibility required by different batches

SOLUTION

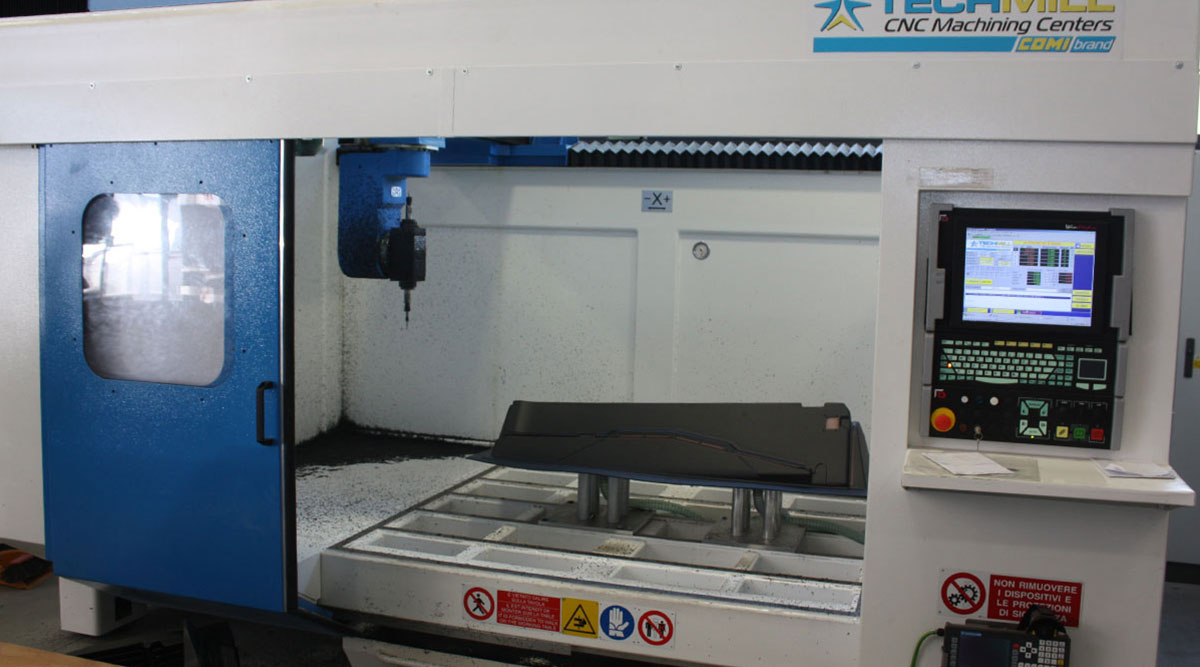

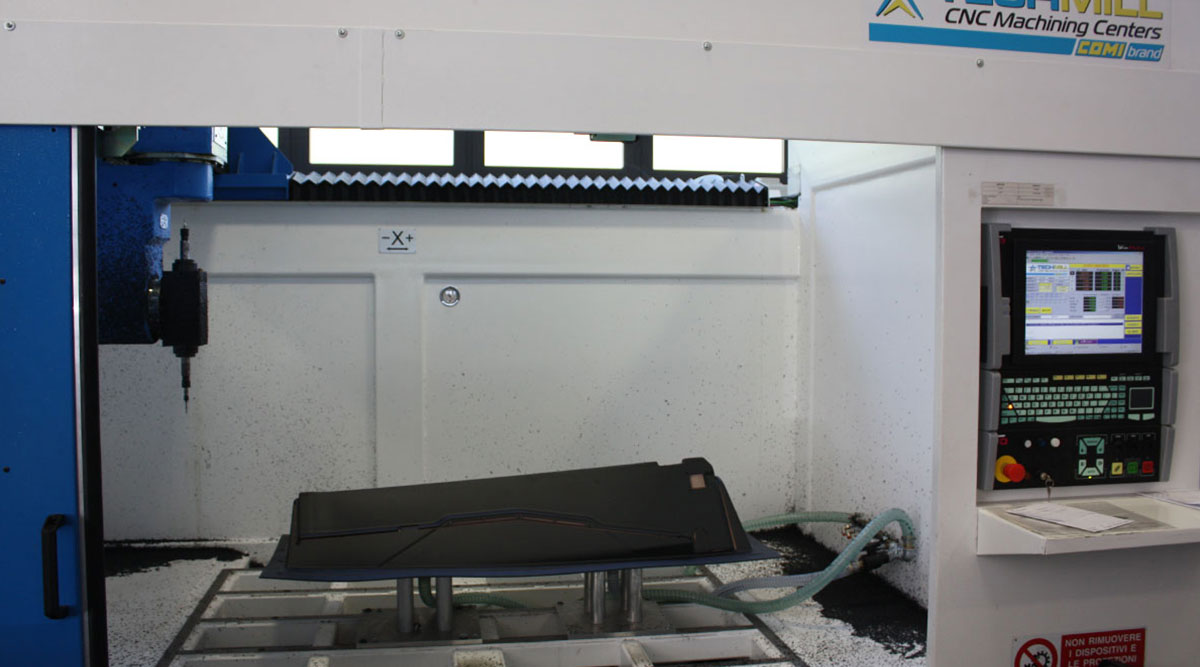

Working on these application conditions, the Self Group Comi Engineering Department has developed an innovative process that integrates:

- LaborForma single-stage thermoforming machines, fully electric, equipped with automatic loader

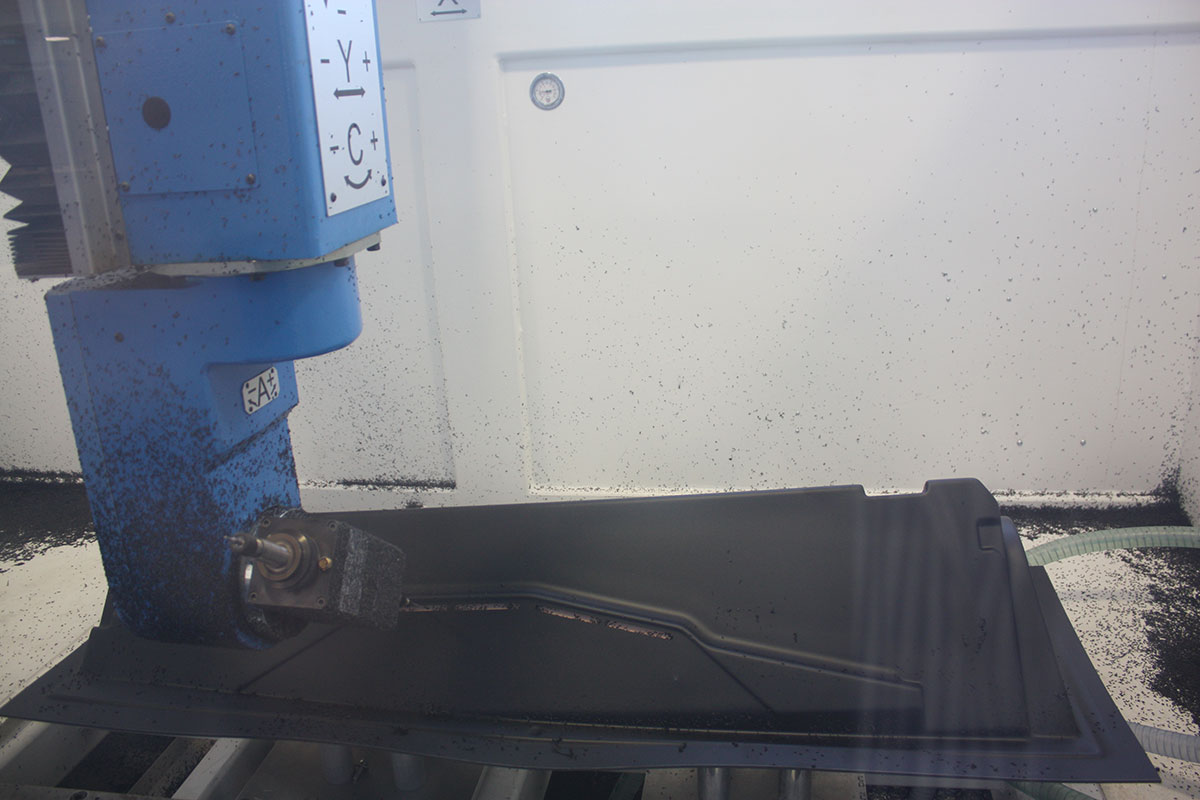

- TechMill 5-axis CNC machining centers

- 3D scanning technologies

- CAD-CAM software.

ADVANTAGES

Repeatable quality and simplification of the process are the main benefits obtained and highly appreciated by leading European companies, which have led Self Group Comi to be the preferred partner for innovation projects in the production of special vehicle fittings