HOUSEHOLD APPLIANCES

About This Project

Improve the production lines of serpentine

for refrigerator condenser

PROBLEM

Traditional large-scale plants are, above all, not very accessible from a maintenance point of view

SOLUTION

Before the intervention of Self Group Comi TÈAS, the main problem on the production lines of condenser serpentines was the considerable size that could reach the rotary table to support the bending group, which has always made these types of production plants not really accessible.

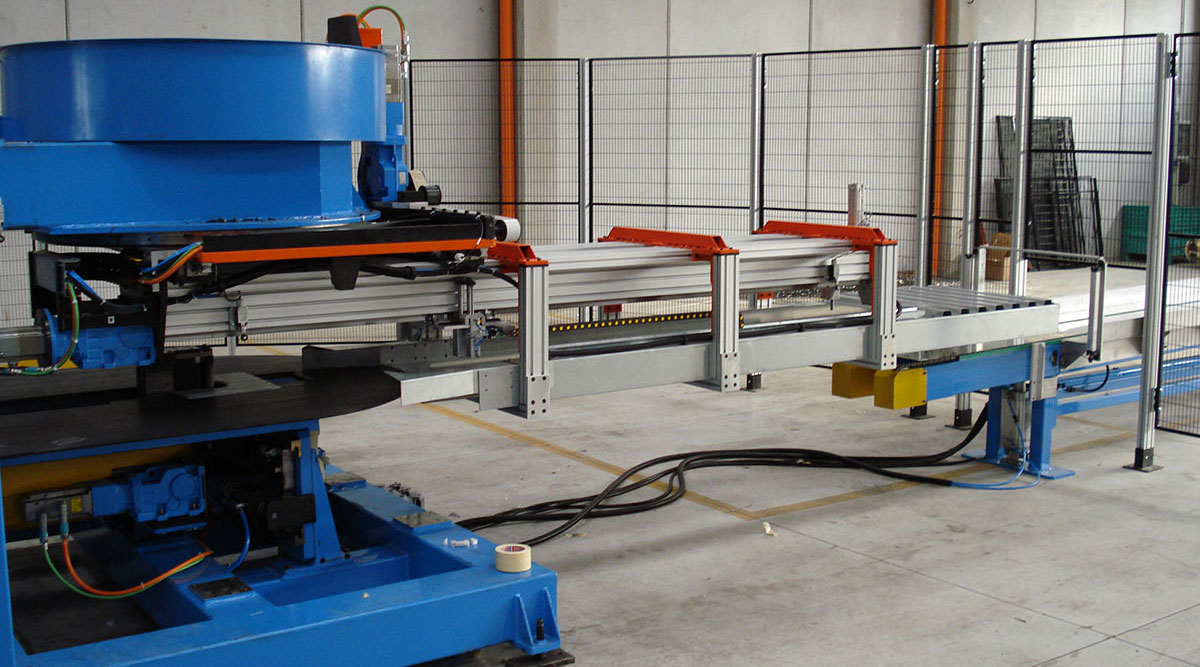

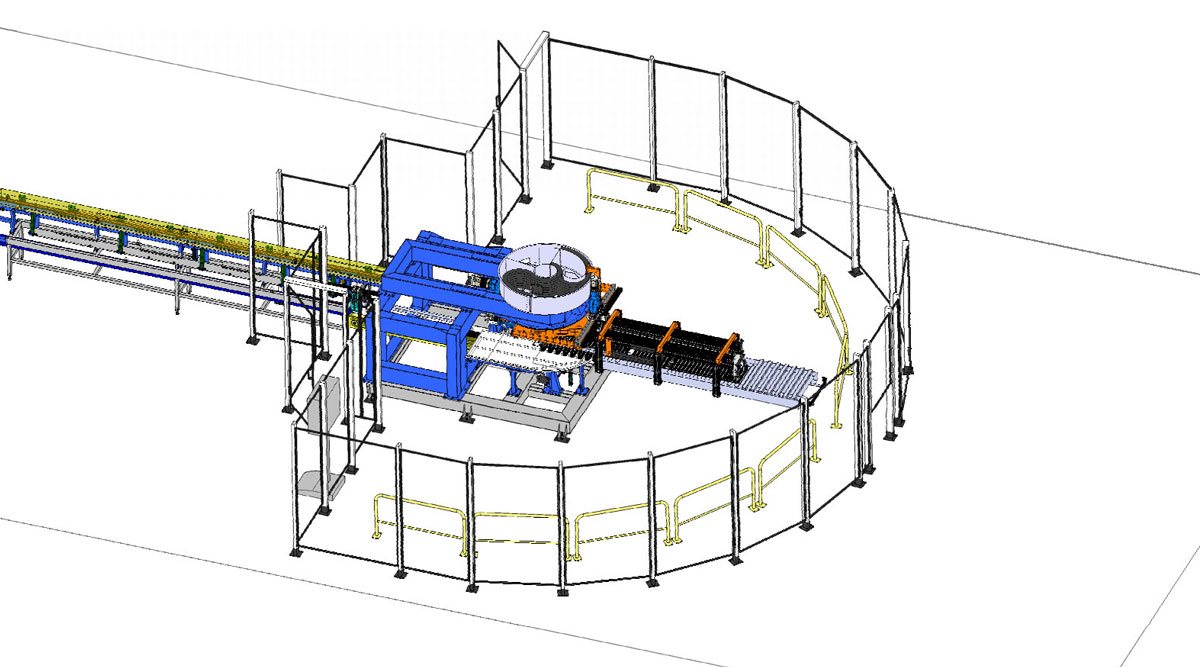

Upon specific request from a customer who is particularly sensitive to this problem, thanks to our methodology, an innovative and dedicated solution has been designed and implemented: the rotary table has been replaced with a more agile rotating trolley to support the bending unit.

In this way the overall dimensions have been reduced, simplifying the machine and making it absolutely accessible from all sides, and secondary impact has been achieved to the ease and speed of installation and transport, a source of savings in terms of time and costs.

ADVANTAGES

Extremely accessible line, reduced dimensions, cleanliness and ease of maintenance, simplified installation in terms of time and costs