LASER T – SLIM T

About This Project

With the LASER T* and SLIM T* compact system, Self Group Comi TEAS has been transforming for years automotive and home appliance production with the versatility and quality of laser technology.

The best companies producing CO2 laser sources and optical fibre partner with us to provide complete robot automated units for plastics and composites parts cutting and finishing and for metal components welding/cutting. We supply systems for specific application in the automotive industry (carpets, plastic components, etc), thermoformed materials (ABS, polystyrene, plexiglas and plastic in general) and composite materials (glass and carbon fibres, kevlar, etc.). Self Group Comi TEAS is the leading company in terms of number of installations made for the thermoformed cells in the refrigerator sector, with various automatic solutions and with cutting speeds up to 400 mm / sec.

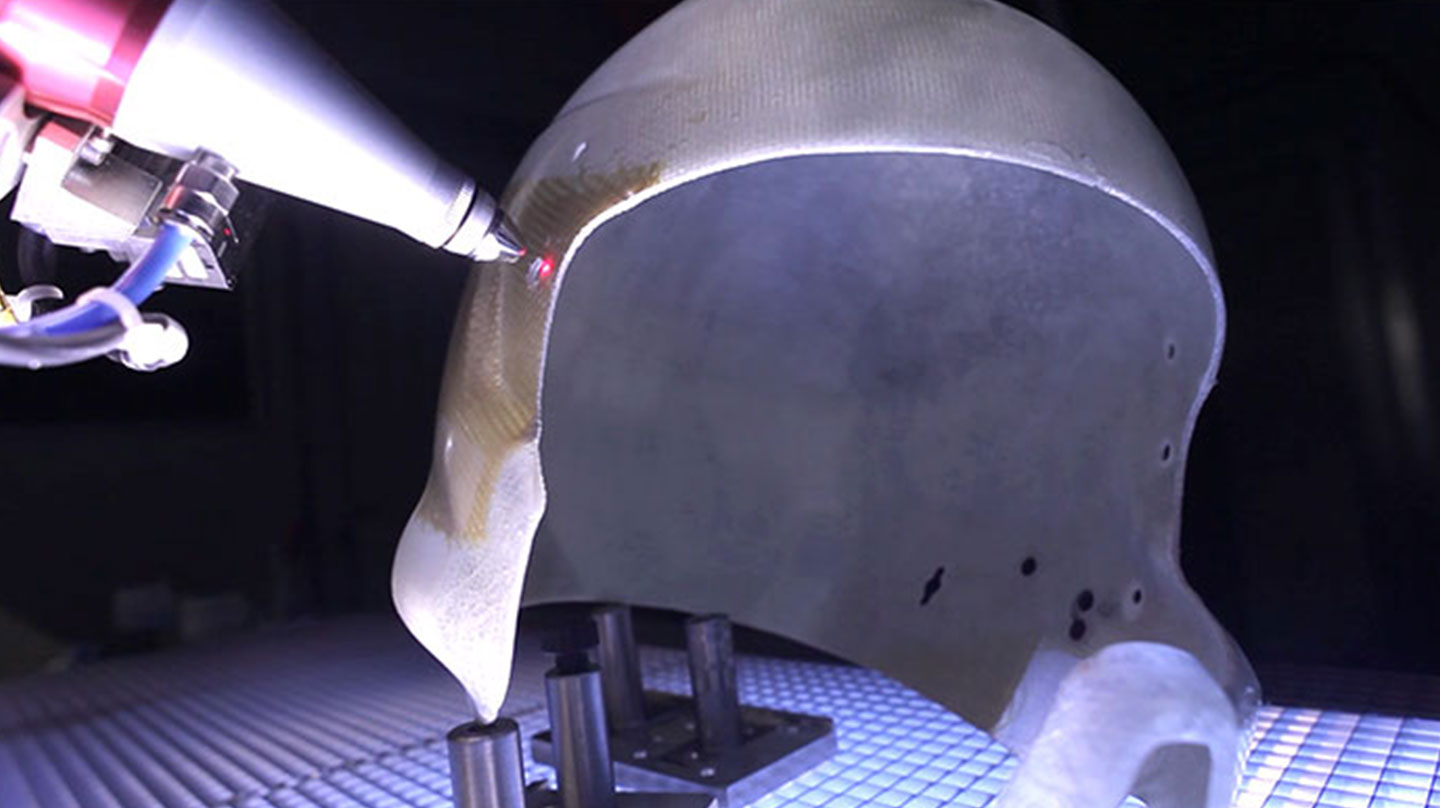

Laser T*

It is an integrated and complete system of cutting or finishing of plastic and composite materials, entirely designed by Self Group Comi TÈAS, which ensures the highest standards of safety, cleaning of the working area and environmental care. It provides a CO2 laser source, whose radius is driven by an articulated arm up to a cutting head moved by a robot. To complete the system there is a special waste collection and evacuation system, as well as a cabin equipped with hazardous substances extraction and filtering system for fumes generated during the cutting process.

Integration with any line

The experience in automation and the engineering capabilities allow Self Group Comi TÈAS to integrate the system into the best plant solution for the specific needs of our customers.

Based on the results of a preliminary tests carried out on the materials used by Customers and at their required production rate, we define the cutting parameters to be achieved for each application and consequently we make the choice of the laser source and optimal cutting head.

Benefits achieved by our customers thanks to the Laser T * system are:

- total flexibility;

- high production rates thanks to the use of cutting heads at very high speed;

- significant reduction of management costs (including no more expenses for consumption of punches, cutters, etc.) thanks to the minimal costs of a laser cutting system;

- reduction of costs to modify/adapt traditional mechanical cutting systems in order to process new product design/models;

- very high quality standards, comparable with those obtainable with other technologies.

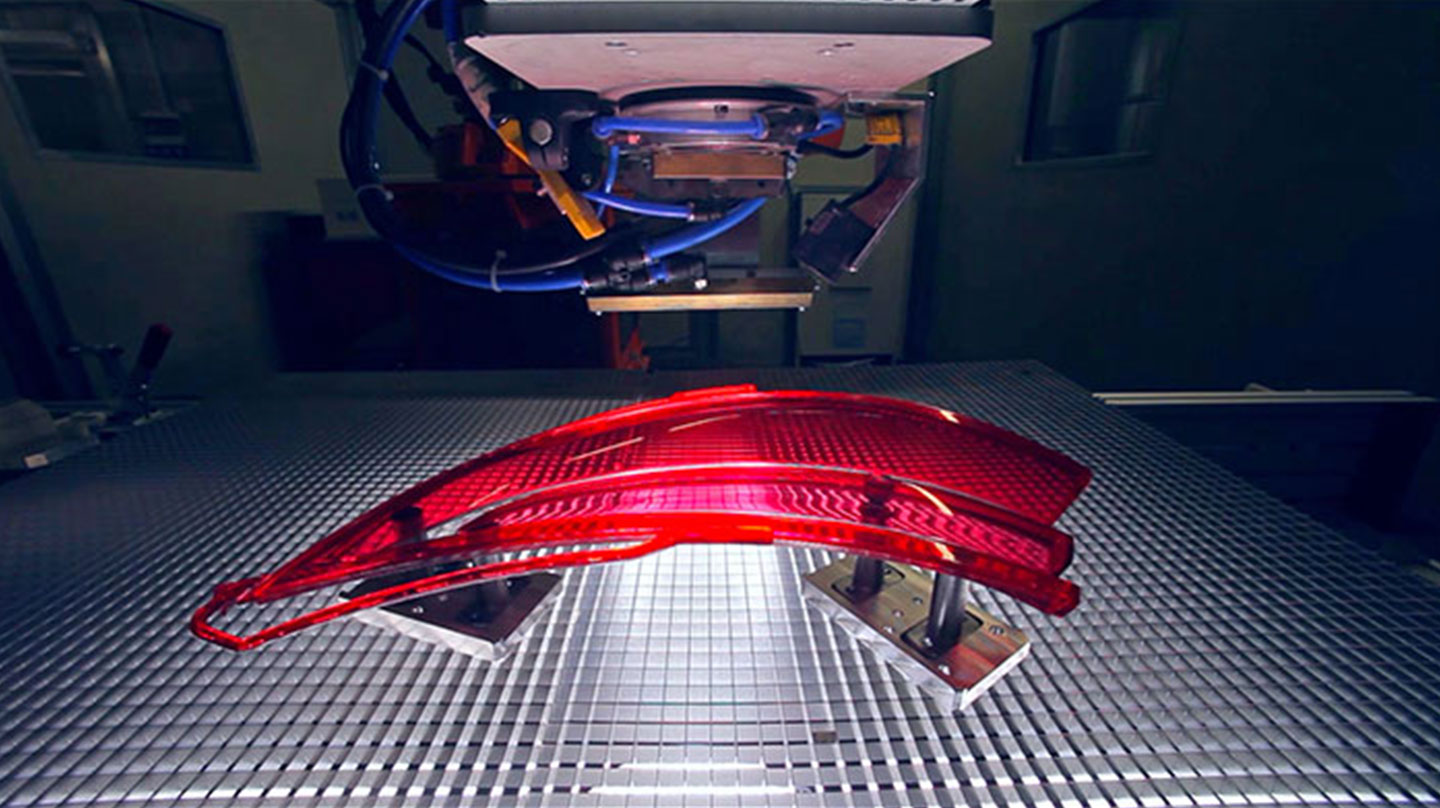

Slim T*

Compact system designed to meet the needs of the automotive sector (and others), which offers the same performances and benefits of the Laser T* system employing an area of only 6 square meters.

The SLIM T * system is particularly suitable to work small components, guaranteeing the same results in terms of flexibility, quality and performance of the largest LASER T * at a low price.

Taking up a total area of less than 2 x 3 meters it is also ideal where space is a limit.

The laser systems advantages that lead to use this technology are:

- the absence of mechanical contact with the workpiece allows to preserve the processed material, and the same time the non-decay over time of the cutting quality (the consumption of punches or mills, for example, entails an inconsistent behaviour of the process over time)

- the spot size can be appropriately adjusted according to the specific application

- surface cleaning (for example, laser systems can be used for all types of composite materials that would otherwise be damaged by a water cutting system)

- the maximum precision of the cutting geometry thanks to the accuracy of modern control systems

- no need to perform second finishing operations on cutting edges such as deburring or smoothing, even at high nominal cutting speeds

- the presence of a special sensor ensures that the correct and constant focal distance during cutting is always ensured, regardless of the surface tolerance of the product