OVEN CAVITY

About This Project

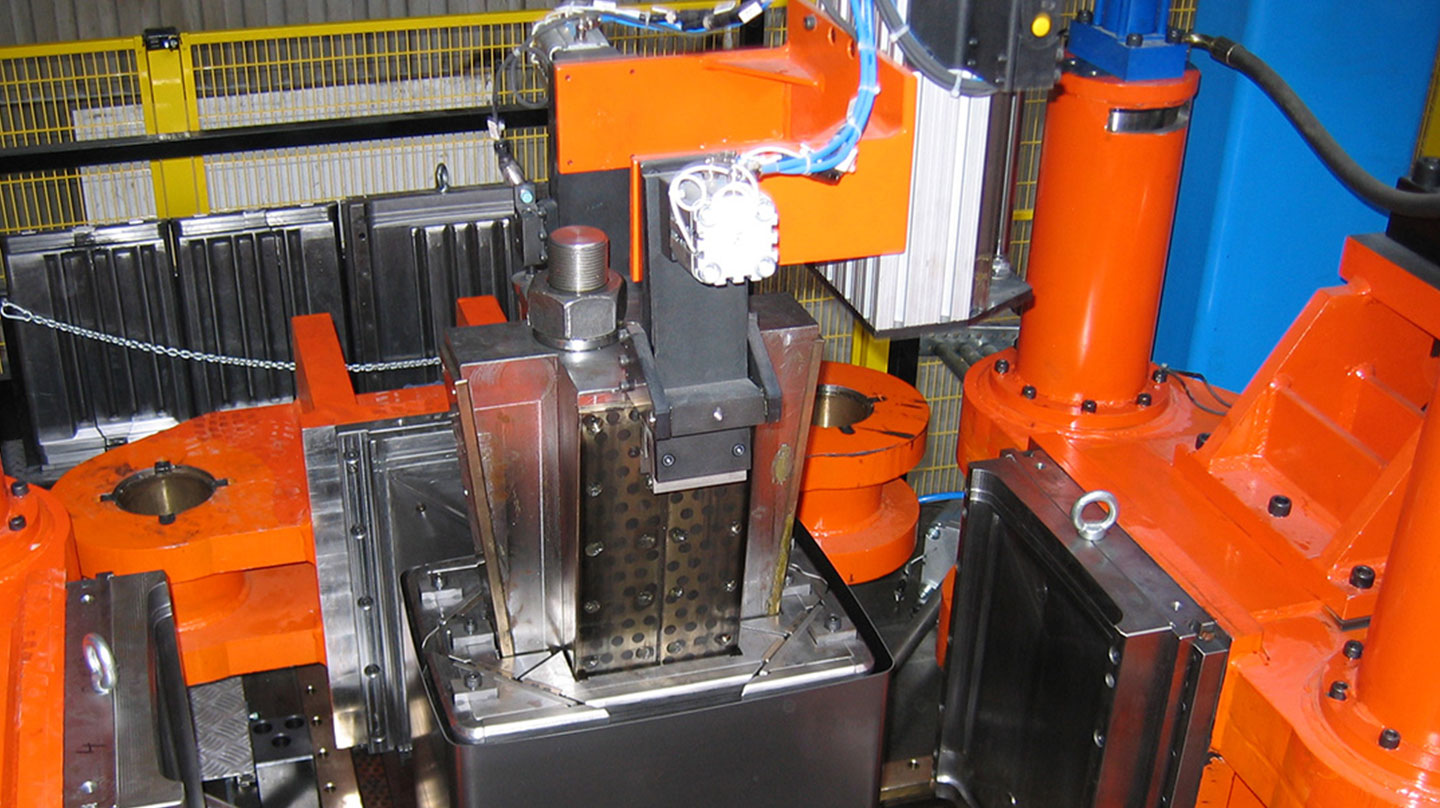

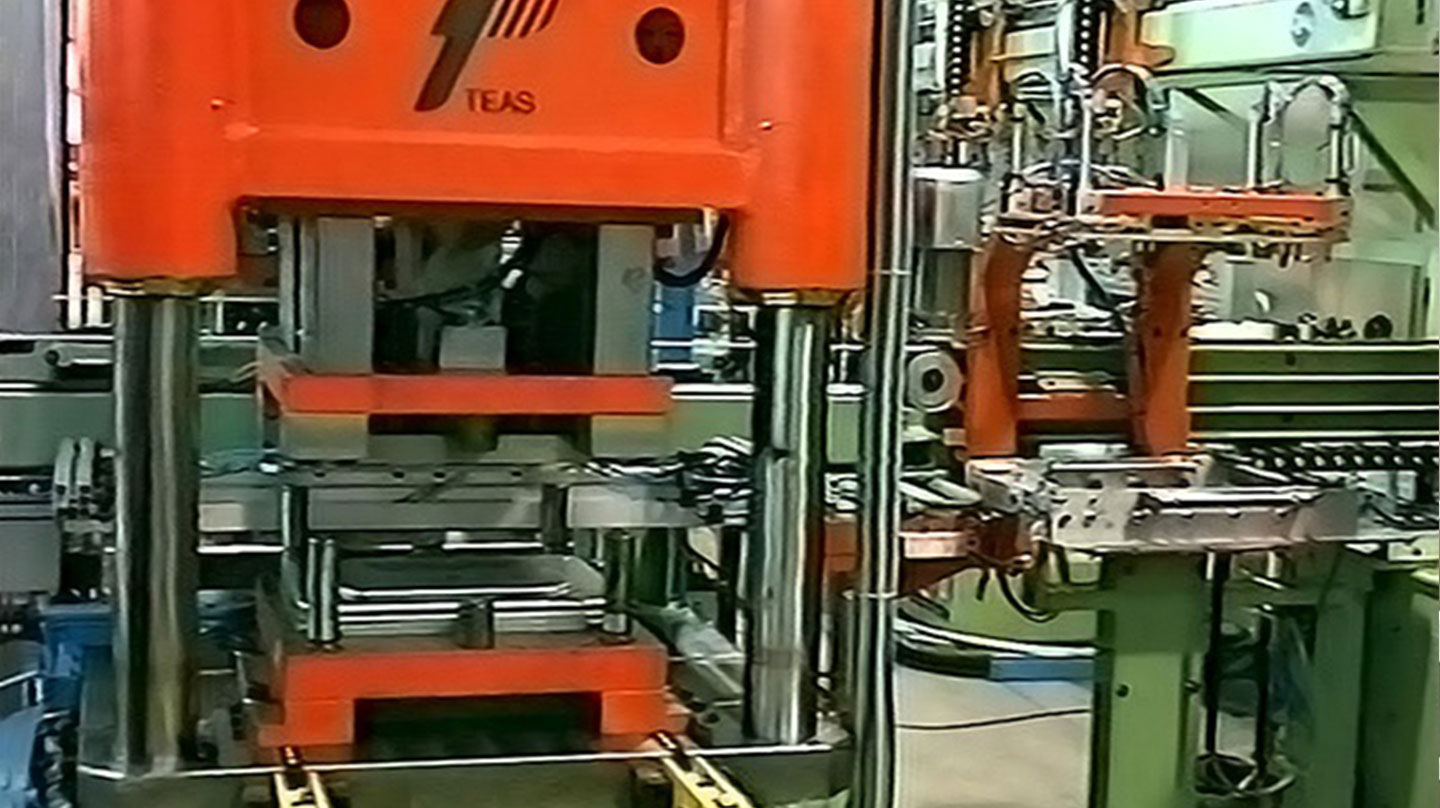

Self Group Comi TEAS designs and manufactures fully automatic and performing systems with the highest degree of customization for the production of cavities for ovens according to the multiple aesthetics proposed by our customers’ R & D divisions

Our systems can realize

- C-shape cavities

- O-shape cavities

- Cavities welded to spot or continuous electrodes

- Clinched cavities

- Cavities welded with laser technology

- Cavities for electric or gas ovens with component assembly

- Expanded cavities

The start of our production lines for the cavities of the ovens can be made either from coils with mechanical presses for the tools of the band or from pre-cut and printed squares.

This concerns both the formation of the cavity and the upper, lower or rear panels.

The range of dimensions and characteristics of the models produced within the same production plant can be completely customized. Trough of automatic and fully integrated transfers, the sheet metal band of the cavity downstream of the bending is then moved through the various work benches according to the specific needs of the model to be produced.

The degree of automation can be naturally modified according to the needs of the customer both for the formation of the cavity in its various phases of assembly and for the processing and enslavement of all the components necessary to ensure final assembly of the cavity itself.

We consider it is useful to underline that we have developed through expander technology, a special solution to create expandable moulds with interchangeable walls, the cavity starting from pre-bent band and longitudinally welded to O, so as to guarantee the maximum precision in parallelism of the lateral support rails.

Self Group Comi TEAS can also realize auxiliary lines for the realization of the cavity wrapper such as the processing of the top, bottom and back panels, of the lateral supporting brackets or of the support plate of the resistance.

Finally, we can integrate in-line process control systems (using laser or scanning sensors) for which we guarantee full compliance with the necessary quality standards required for the specific type of product.

Self Group Comi TEAS supplies its lines equipped with complete sets of the highest quality tools, completely made in Italy.