SPRAYING, MILLING AND CUTTING

About This Project

In collaboration with the Research and Development office of its customers, Self Group Comi designs and manufactures highly automated working units for spraying resins and milling / trimming the parts thus produced

This innovative working unit has been designed to achieve three operations in the same environment:

- Spraying polyurethane reinforcing / insulation foams on specially designed templates

- Leveling milling of the cured and hardened foam layer

- The perimeter cut of the machined part.

Machine structure

The structure of the machine guarantees maximum operator safety:

- Fully closed cabin, completely closed by perimeter padding and steel roof

- Layer of sound-absorbent material and internal coating, optionally added to comply with the noise limits required by the operator’s acoustic exposure regulations

- Automatically operated front doors and side access door

- Protection of the working area outside the cell with photo-electric barriers.

Working Table

The project is customized to promote high accessibility and flexibility in the management of workpieces:

- Twin Shuttle system with translating or slide-through tables mounted on trolleys, operated independently or jointly, allowing the loading / unloading of the pieces in masked time

- System with fixed tables, with the possibility of transversal translation inside the unit in case of pieces higher than the robot arm

- Pumps for vacuum application aimed at clamping the pieces on the templates.

Spraying and milling unit

Thanks to a specific head changing system, the unit can spray two-component resins through an operating unit consisting of:

- High pressure machine for dispensing

- Automatic mixing head

- Pipes, tanks and loading pumps, kits for dehumidifying materials drums, and other accessories

or it can alternatively perform the milling of the hardened bicomponent material and the perimeter cut of the parts through a second operative unit composed of:

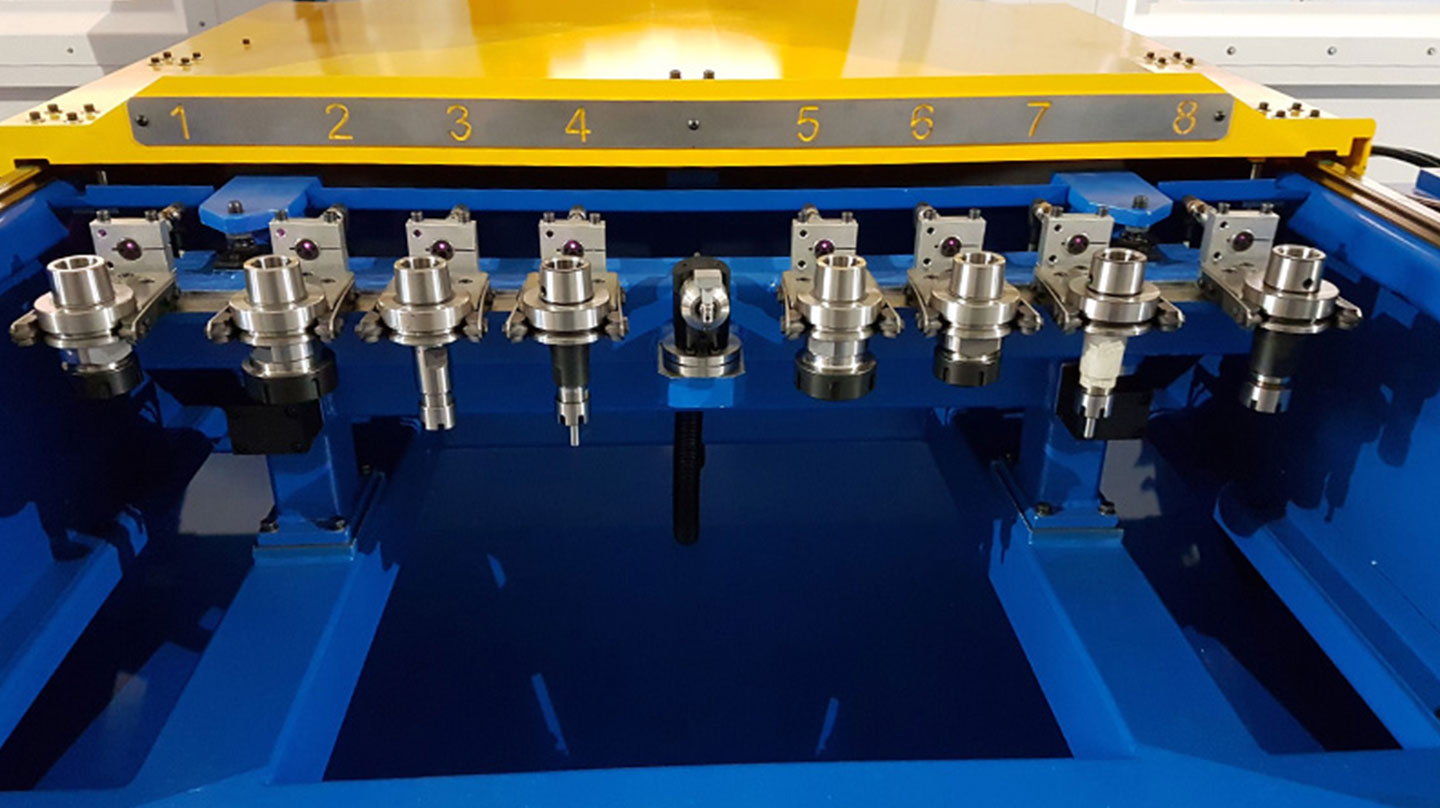

- Electro-spindle with automatic tool change

- Tool magazine with 8 or more positions, equipped with tool holders and cones

- “Tool setter” device for tool measurement, with system for aligning the rotating axes A and C

Robot & software

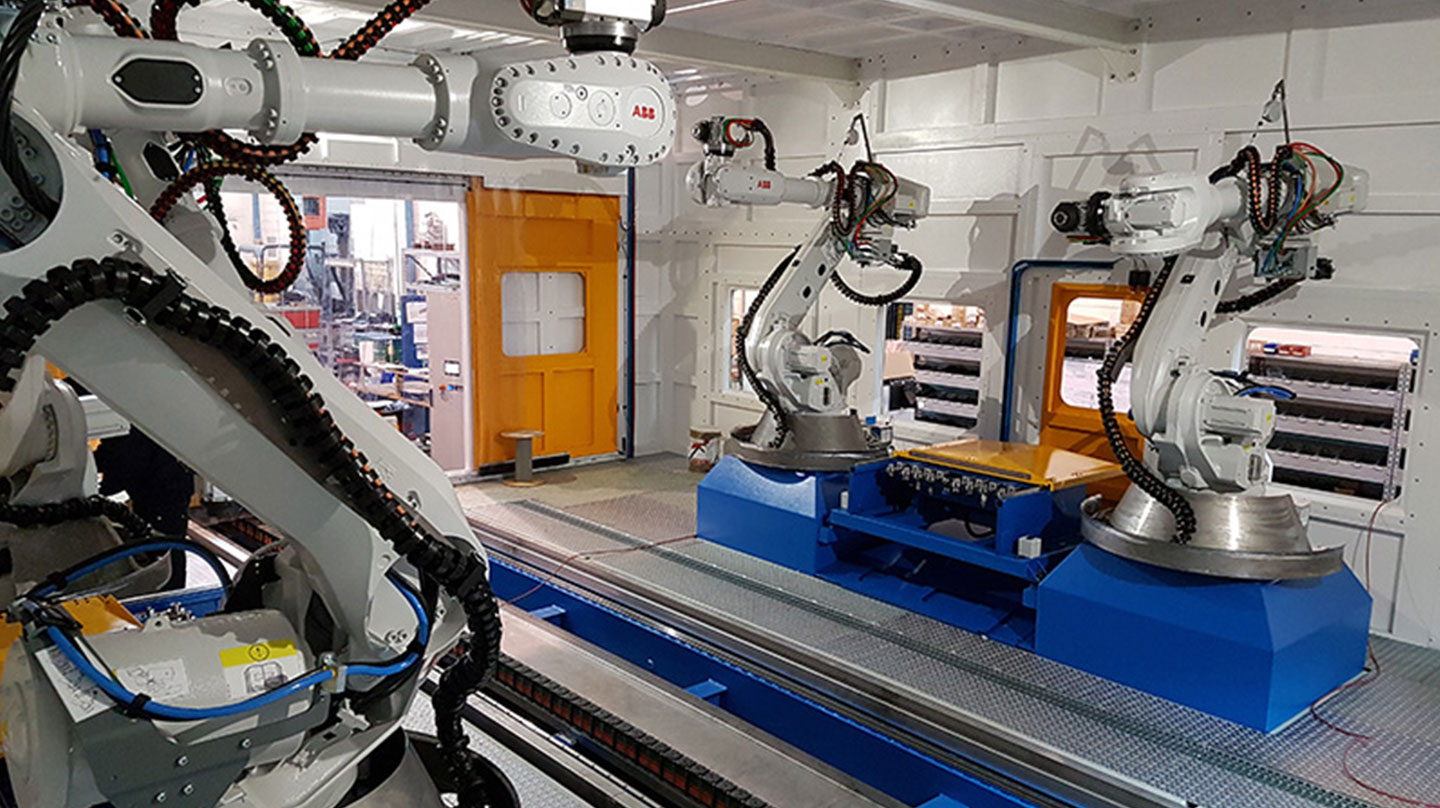

- 6-axis anthropomorphic robots, in number and size suitable for the required productivity

- Mounted on a fixed platform, or on a longitudinally moving carriage to allow machining of parts larger than the robot’s reach

- Robot control unit

- Software for programming the robot

Self Group Comi is able to provide turn-key working units which integrate systems and equipment such as:

- Automatic identification and blocking systems for parts

- Molds designed according to customer drawings and completely made in Italy

- Filtration systems of dusts generated by milling / cutting operations

- Air purification systems from volatile organic substances present during spraying

- CAM software for workpiece machining