Monnalisa

About This Project

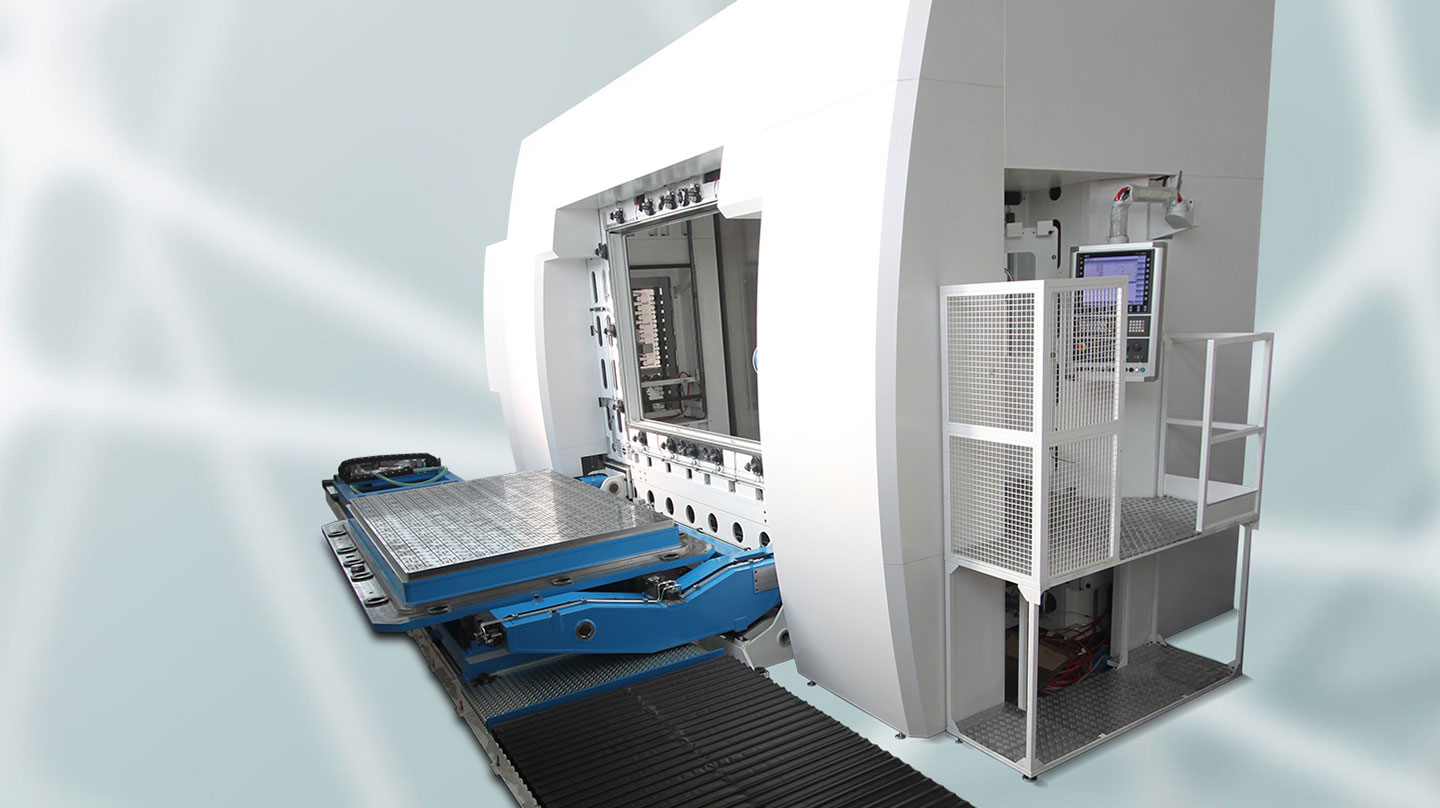

Monnalisa is the innovative horizontal 5 axis milling centre specifically developed for machining monolithic, structural, large dimension aluminum parts, particularly suitable for aerospace industry applications

The axis strokes and the attention to their movement

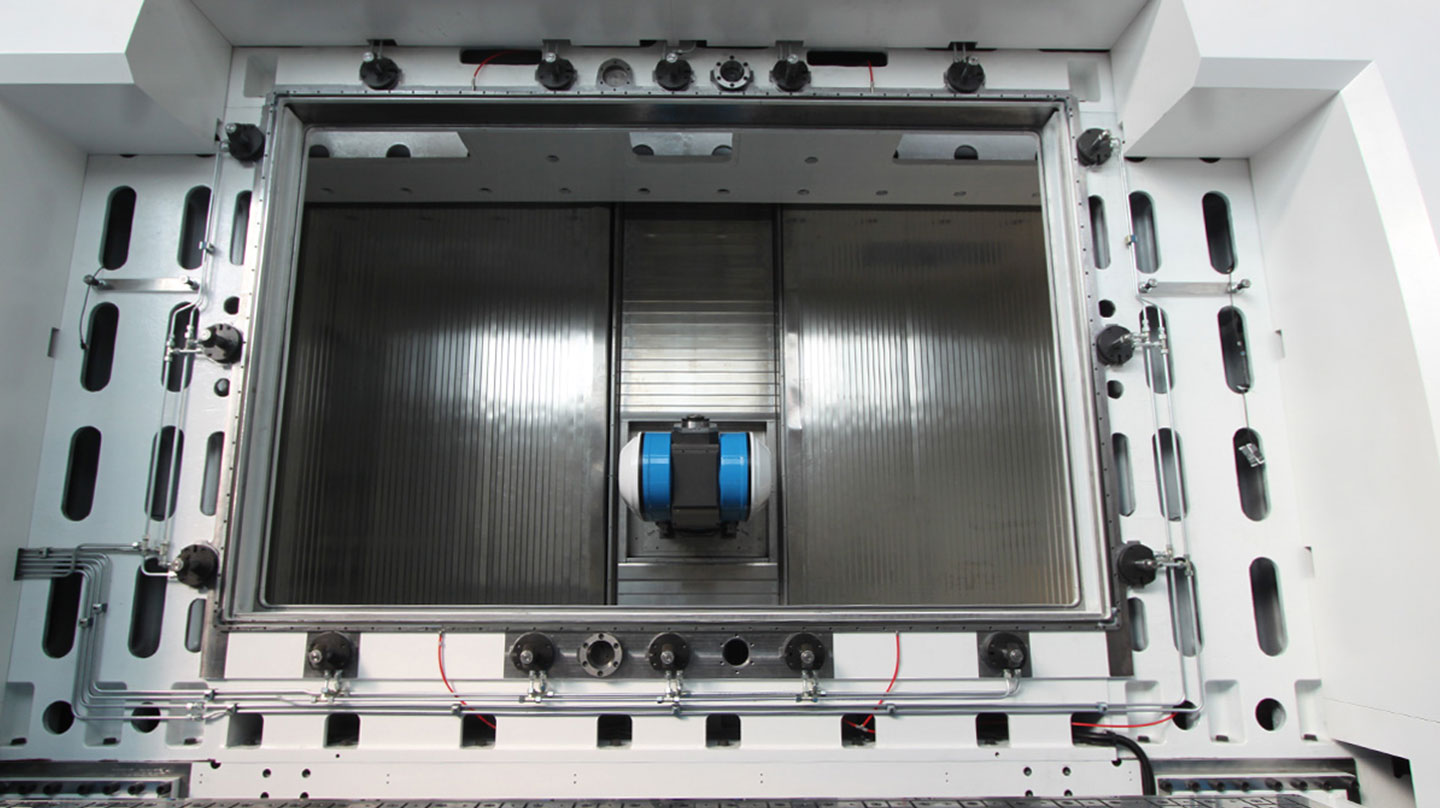

The X carriage consists of a rigid double column in cast iron and it is moved by 4 gearboxes with integrated pinion and 4 brushless motors. The Gantry configuration presents two Twin Drive systems for the recovery of any backlash through an electronic preload.

The Y axis is mounted on roller sliding blocks which slide on guides housed on the axis X fusion; the Z axis is made by a parallelepiped rectified structure which slides on roller sliding blocks, whose guides are housed instead on the Y axis fusion.

The cross system vertical axis/RAM, respectively Y axis and Z axis, is made by two integrated structures Box in Box.

The carriage position is detected by optical encoded and pressurized lines, made by Heidenhain.

Extremely robust structure, in cast iron

The machine structure is built in cast iron and reinforced in strategic points, giving therefore also great rigidity and dynamics, with the minimal temperature drift. The machine is equipped with PT100 temperature detection, used for any eventual upgrading.

Large capacity automatic tool changer

Rack with 120 tools positioned on the side and properly protected by working chips as well as dust when not used.

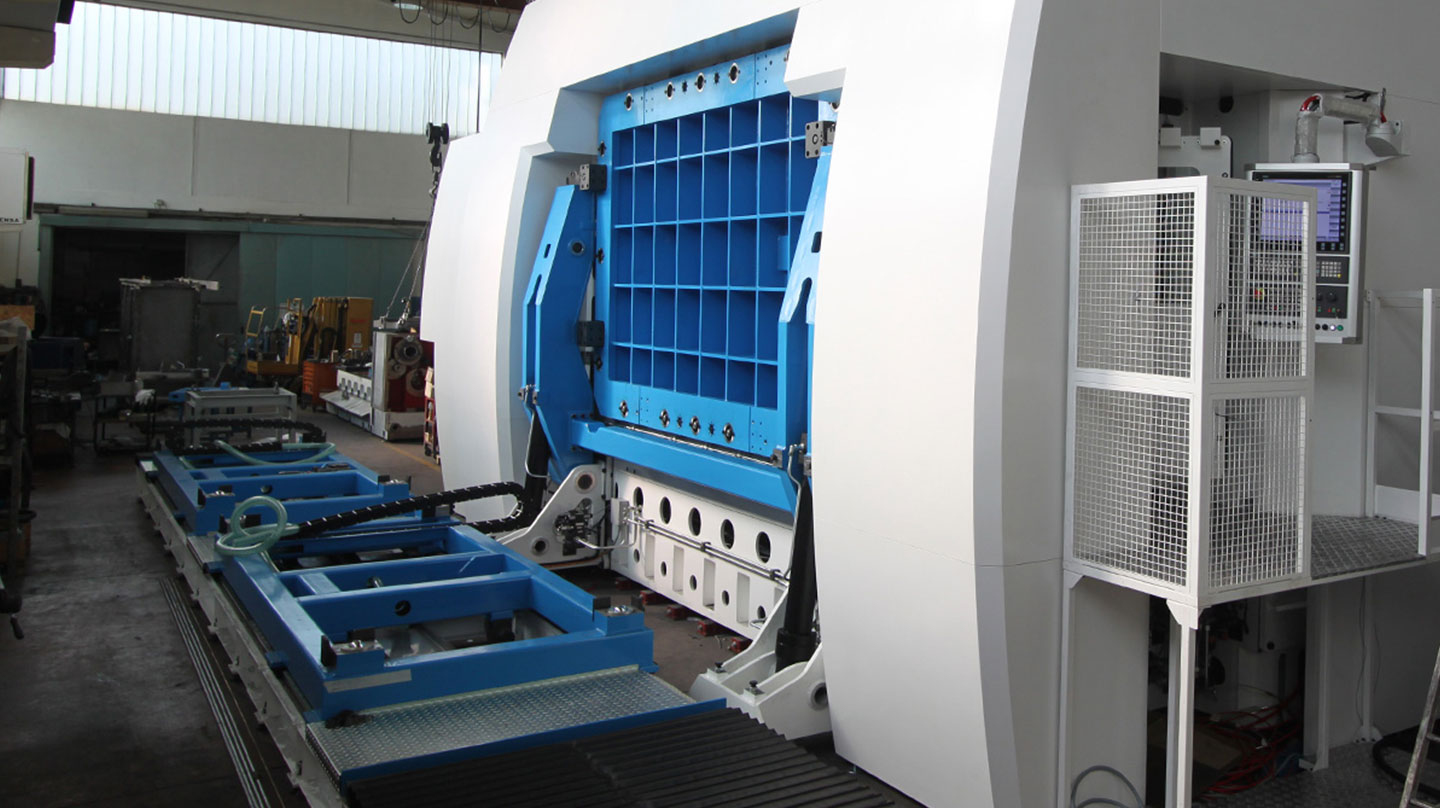

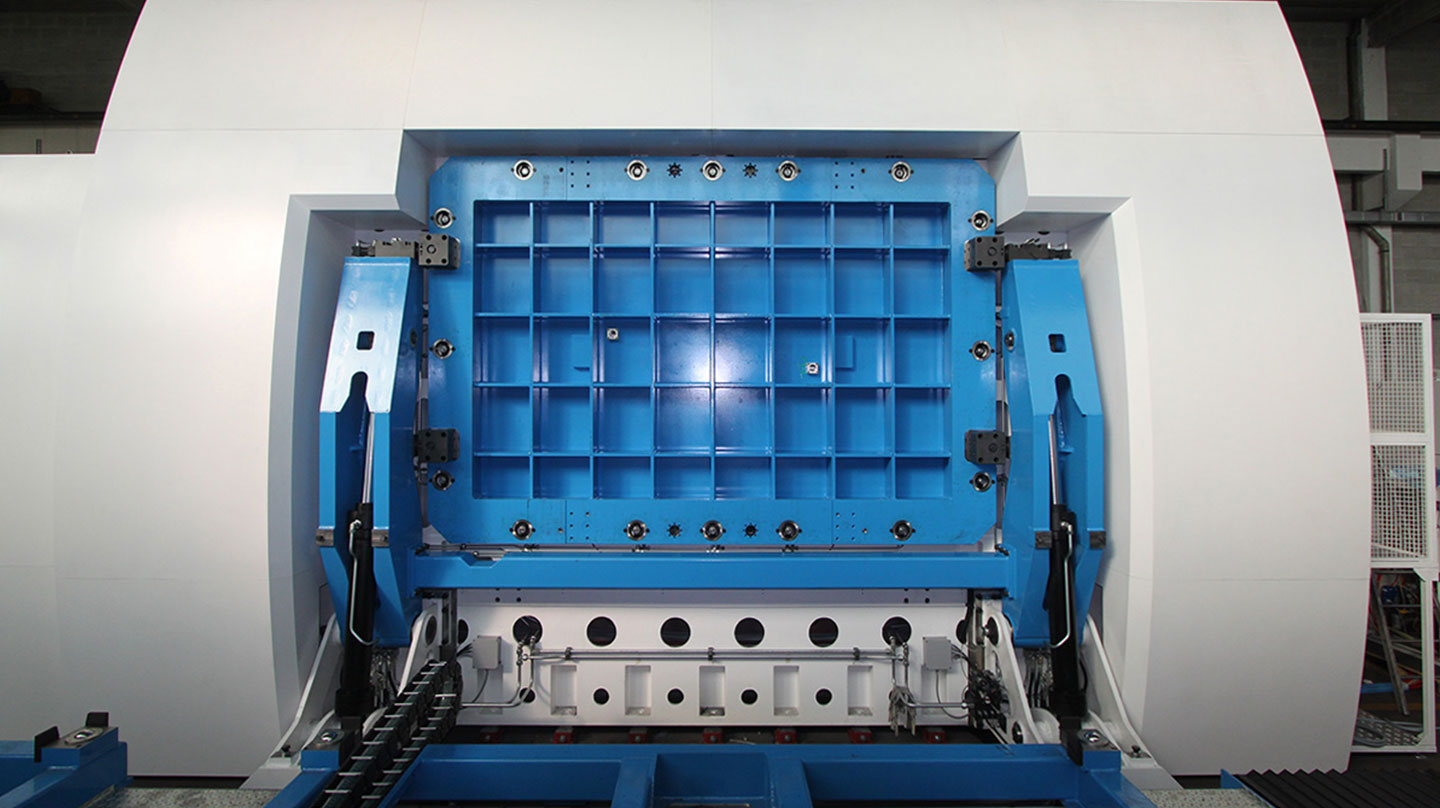

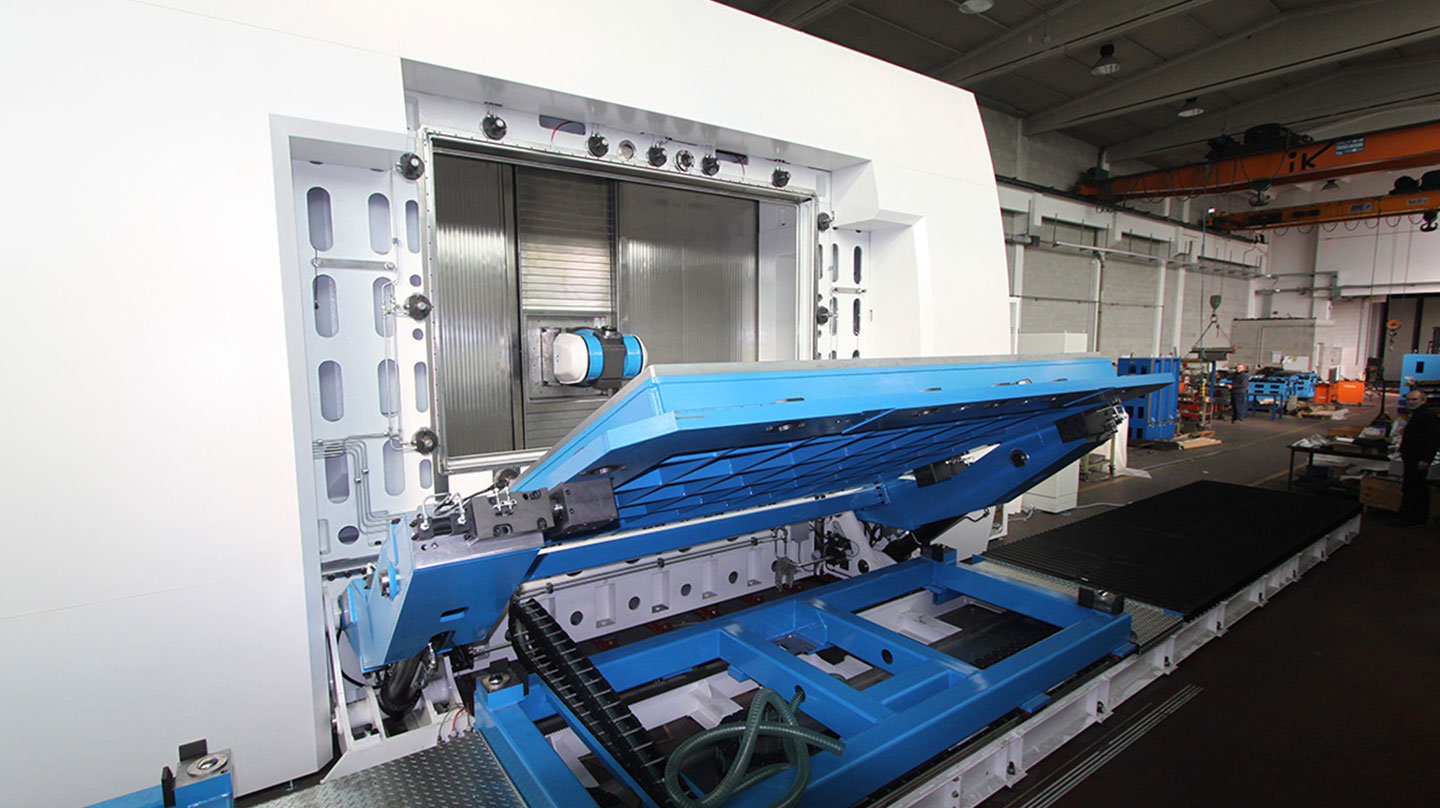

Double working table, pallet change type

The working tables are made by two large dimension working plates (3200 x 2000 mm), symmetrical (pallet change) to allow replacing of the pieces during the machining cycle.

The aluminum working tables have been developed to use vacuum extraction and any system of clamping piece, with a capacity of 2000 kg each plate (total weight admitted on the working tables kg 8000).

The movement of the two tables, pendular type, is obtained with carriages moving on a sliding line.

The area of the piece substitution ensures the easiest position to the operator during the replacing’s phases, working in full safety.

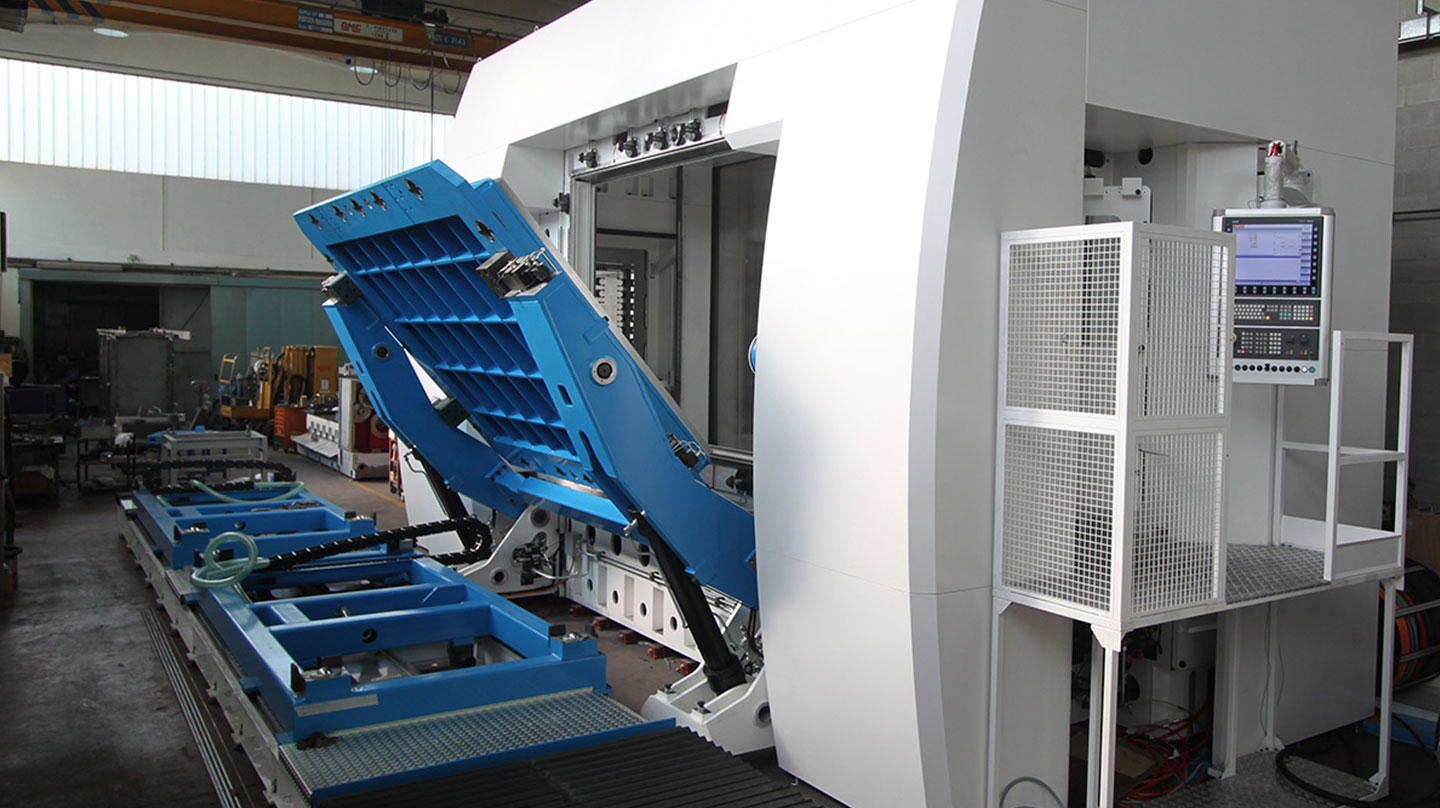

Easy loading operations thanks to table rotation

Loading operations are made easily by the ± 90° table rotation obtained by two mechanical arms hydraulically operated, while for the table gripping are used four hydraulic pistons.

Large volume of chips evacuation

Thanks to a large dimension belt chip conveyor (800 mm width, 300 mm height) positioned under the working area, a volume of about 1 cubic meter/hour is evacuated.

Technical data

| Axes Strokes | Axes Speed | |

| X | 3.200 mm | 50 m/min |

| Y | 2.000 mm | 50 m/min |

| Z | 1.000 mm | 50 m/min |

| A(*) | +/- 110° | 140° /sec |

| C(*) | +/- 200° | 140° /sec |

NOTES: (*) Variable depending on the head type

Spindle features

| Power | 95 kW |

| Torque | 29 Nm |

| Speed | 500 – 30.000 rpm |

| Taper | HSK F80 |

Materials

Aluminum

Steel