chrome

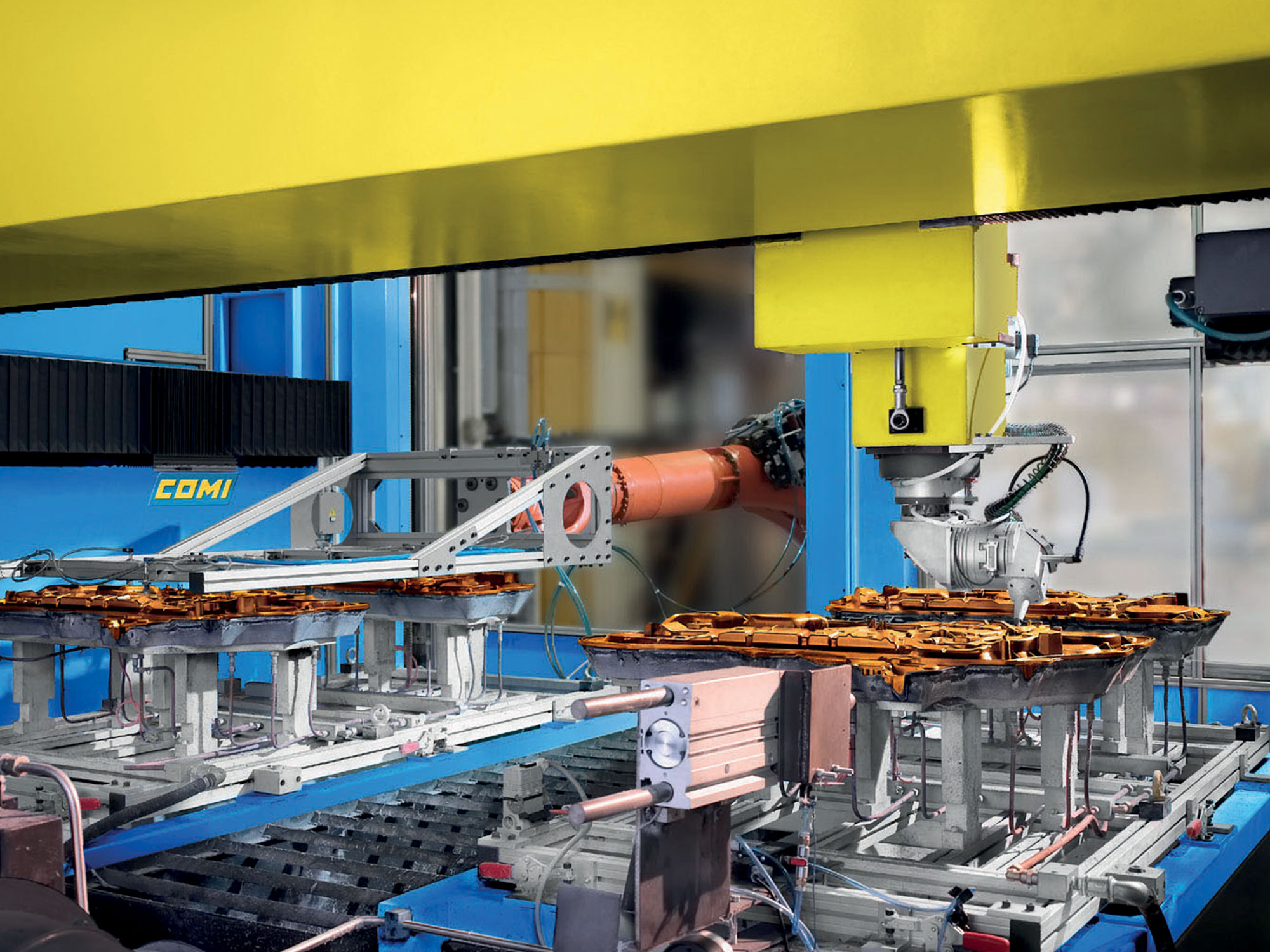

The CHROME – R presses have been studied for the compression molding of technical rubber items. They are 4 columns presses with upward movement of the movable platen. The CHROME – R presses can be equipped with: T – Bottom sliding platen V – Vacuum chamber DD – Double...