Basic/SuperLine New Generation

About This Project

The thermoforming machines model BasicLine and SuperLine of New Generation line, are a universal system suitable for the production of household refrigerator inner doors and liners, which does not need any additional adjustments: a series of in line stations make fully automatic the forming process of plastic materials in sheet (ABS and HIPS) with thickness from 0,5 to 8 mm.

Compared with the standard line, the forming process is here obtained through the establishment of vacuum in the mould, while the bubbling stage of the material is executed by a “bell” located in the upper section of the forming station. It is possible to use 2/4 bar compressed air (Pressure Forming) inside the bell during the material’s forming process and also the Cooling System, a rapid cooling of the thermoformed part.

Inner liners

| HIPS | 4 mm – 0,157 inch | Fino a 100 p/h (65-85 p/h side-by-side) |

| ABS | 3,1 mm – 0,122 inch | Fino a 100 p/h (65-85 p/h side-by-side) |

Inner doors

| HIPS | 1,5 mm – 0,069 inch | Fino a 300 p/h (SL) Fino a 250 p/h (BL) |

| ABS | 1,4 mm – 0,055 inch | Fino a 300 p/h (SL) Fino a 250 p/h (BL) |

Standard dimensions

2000 x 900 x 600* mm | 78,7 x 35,4 x 23,6* inch

2100 x 1250 x 600* mm | 82,6 x 49,2 x 23,6* inch

2200 x 900 x 600* mm | 86,6 x 35,4 x 23,6* inch

2000 x 1000 x 600* mm | 78,7 x 39,3 x 23,6* inch

2200 x 1000 x 600* mm | 86,6 x 39,3 x 23,6* inch

*dephts of the moulded pieces available up to 800 mm

LOADING

• Sheet

HEATING

• One station in BasicLine, two for SuperLine • IR ceramic, quartz, or fl ash black heating elements

FORMING

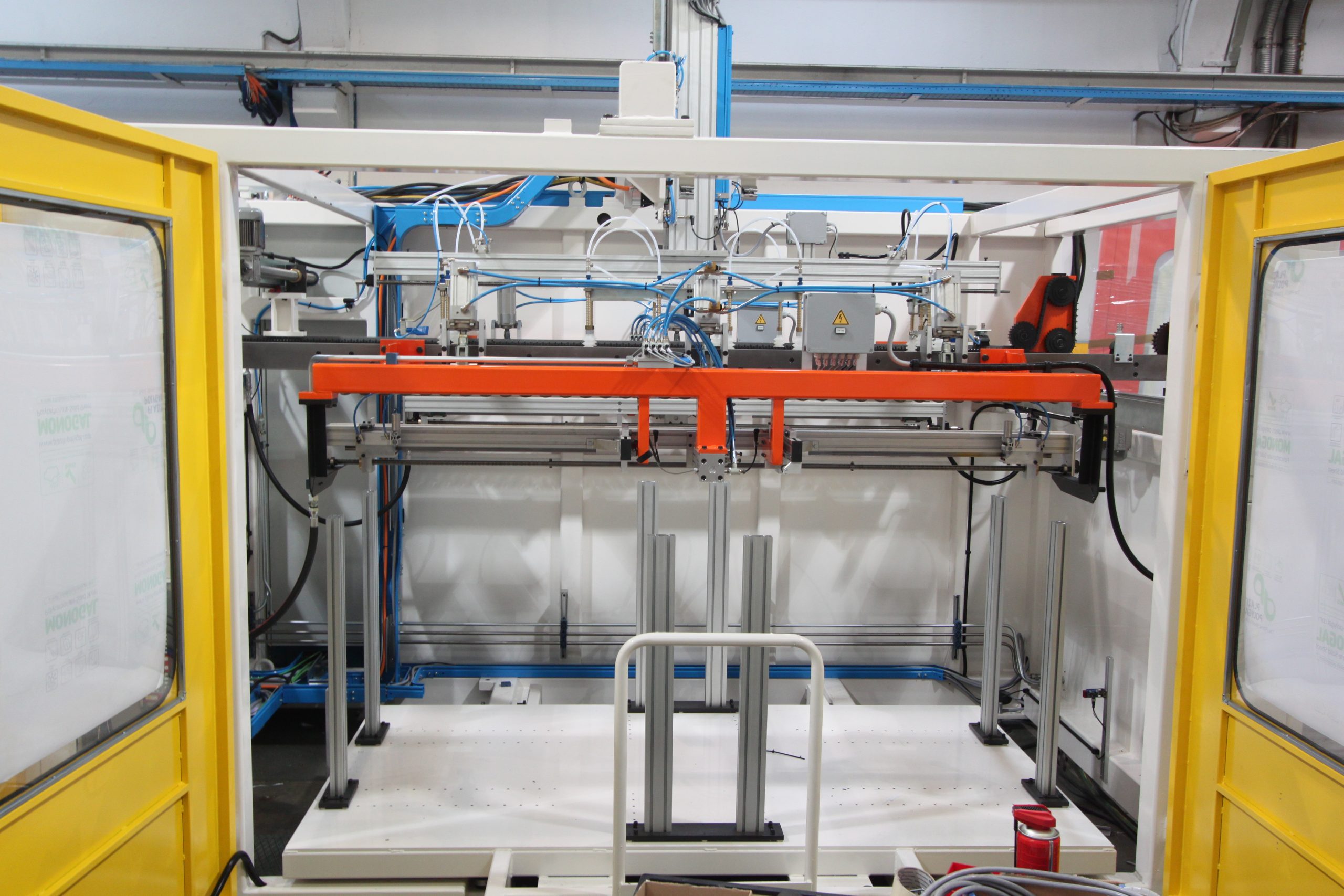

• Forming by vacuum in the mould and ballooning through a bell located in the upper part of the heating station • Bell capable to work with positive molds with 2 similar or different shapes (Side-by-Side) • Cooling system to quickly cool down the thermoformed part • Positive or negative moulds

CUTTING

• Perimetral cut by guillotine or presse