LABORFORMA SHEET SINGLE STATION

About This Project

The LaborForma serie’s thermoforming machines are suitable for working plastic materials HIPS / ABS / PMMA / PP in cycle, with thickness up to approx. 8 mm and PVC up to 3 mm. If equipped with dedicated accessories, they can also process materials reel-to-reel up to approx. 1 mm if rigid, higher if flexible.

These machines are suitable for the production of any thermoformed article: articles for the bathroom furniture (bathtubs, tubs, shower trays, shower walls), articles for household appliances (refrigerators, containers, vacuum cleaners), illuminated signs, helmets, etc.

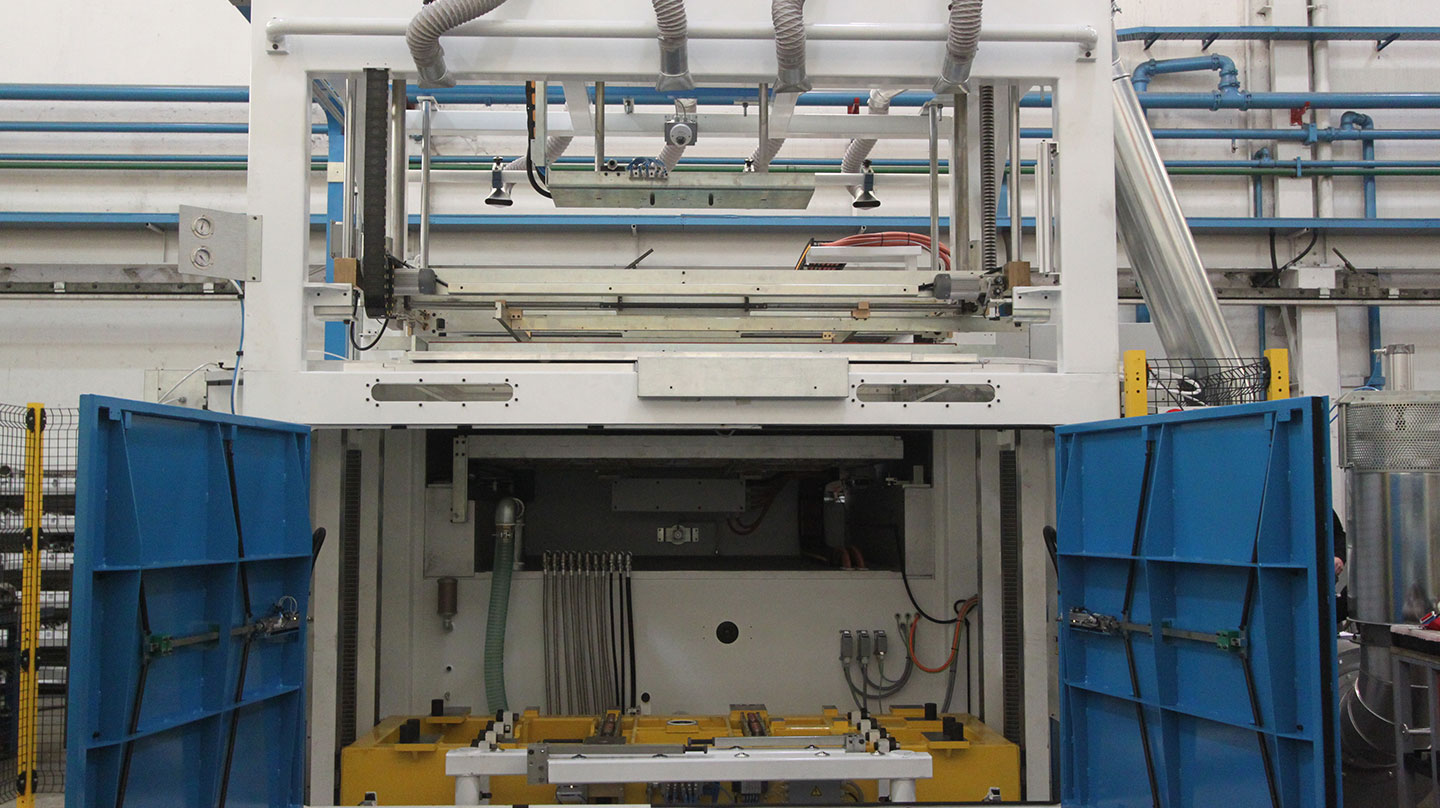

Laborforma is a one working station machine, where plastification and forming take place.

The material loading/unloading is manual, or automatic if conceived with a specific optional. Moulds whose forms can be positive or negative relating to the material sliding line are used.

All LaborForma industrial thermoforming machines are manufactured according to CE rules and provided with:

Manual sheet loading

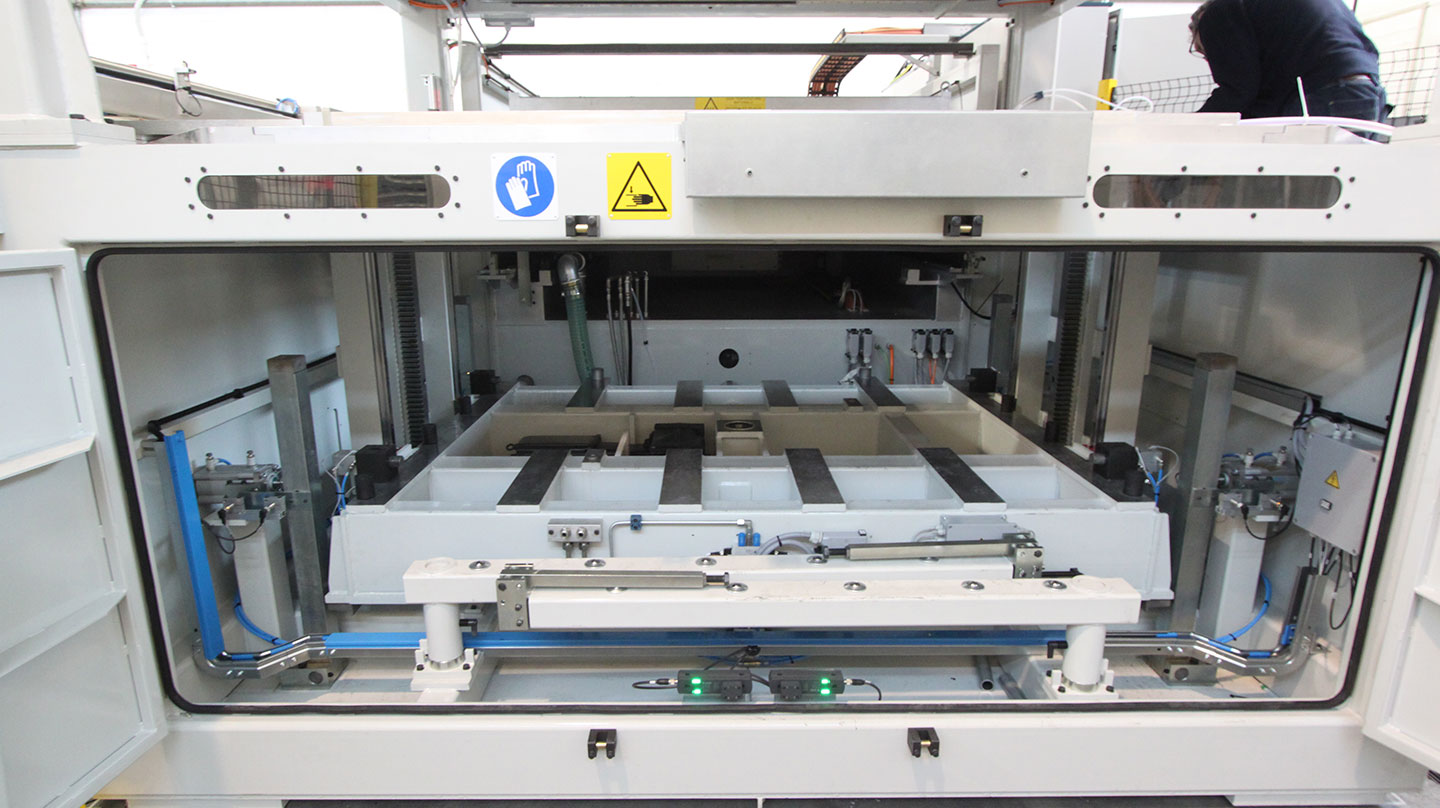

Sheet clamping system

Forming station with plug assist system

Bilateral sheet heating system with ceramic heaters

Cooling system with fans

Vacuum system

PC with color display screen and control software

All the machines may be equipped with the following optional

Automatic sheet clamping adjustment with motors (Patent)

Automatically adjustable window frame with motors (Patent)

Automatic mould plate clamping

Mould drawing carriage

Automatic sheet loader

Unwinder

Pre-heating unit

Quartz or halogen heating elements with ceramic-glass protection

Remote diagnostics

Heating systems

Each eating panel may be equipped with different type of heaters, chosen according to the end user’s requirements among ceramic heaters, either standard or high-efficiency, quartz heaters, flash heaters (halogen).

Dimension of heating elements are selected according to the product type to be thermoformed.

The optional configuration of the machine includes also the installation of an IR pyrometer, which assures a correct thermoforming of each sheet, in particular when different temperature values are involved.

The system with servomotors

The core of the thermoforming system is the powered handling controls of mold plate, plug assist and material clamping tools. The use of servomotors, allows to improve:

Handling accuracy;

Output rate, with increase in cycles/hour number thanks to higher moving speed;

Machine noise level decrease, plus no environmental contamination because the oil-dynamic power unit is not used anymore.

Machines

| MACHINE MODEL | MAX FORMING AREA | MAX SHEET SIZE | MAX TOOL HEIGHT | HEIGHT OF WORKING SURFACE | VACUUM PUMP |

| LF 12.08 | 1250 x 800 mm 49,2 x 31,5 inch |

1300 x 850 mm 51,2 x 33,4 inch |

500 mm 19,7 inch |

1265 mm 49,8 inch |

70 m3h 2472 ft3h |

| LF 15.10 | 1500 x 1000 mm 59,0 x 39,3 inch |

1550 x 1050 mm 61,0 x 41,3 inch |

500 / 700 mm 19,7 / 27,5 inch |

1265 / 1465 mm 49,8 / 57,6 inch |

70 m3h 2472 ft3h |

| LF 15.13 | 1500 x 1300 mm 59,0 x 51,2 inch |

1550 x 1350 mm 61,0 x 53,1 inch |

500 / 700 mm 19,7 / 27,5 inch |

1265 / 1465 mm 49,8 / 57,6 inch |

70 m3h 2472 ft3h |

| LF 20.10 | 2000 x 1000 mm 78,7 x 39,3 inch |

2050 x 1050 mm 80,7 x 41,3 inch |

700 / 900 mm 27,5 / 35,4 inch |

1480 / 1680 mm 58,2 / 66,1 inch |

165 m3h 5827 ft3h |

| LF 20.15 | 2000 x 1500 mm 78,7 x 59,0 inch |

2050 x 1550 mm 80,7 x 61,0 inch |

700 / 900 mm 27,5 / 35,4 inch |

1480 / 1680 mm 58,2 / 66,1 inch |

165 m3h 5827 ft3h |

| LF 25.15 | 2500 x 1500 mm 98,4 x 59,0 inch |

2550 x 1550 mm 100,4 x 61,0 inch |

700 / 900 mm 27,5 / 35,4 inch |

1480 / 1680 mm 58,2 / 66,1 inch |

165 m3h 5827 ft3h |

| LF 25.20 | 2500 x 2000 mm 98,4 x 78,7 inch |

2550 x 2050 mm 100,4 x 80,7 inch |

700 / 900 mm 27,5 / 35,4 inch |

1530 / 1680 mm 60,2 / 66,1 inch |

250 m3h 8828 ft3h |

| LF 30.20 | 3000 x 2000 mm 118,1 x 78,7 inch |

3050 x 2050 mm 120,0 x 80,7 inch |

700 / 900 mm 27,5 / 35,4 inch |

1530 / 1730 mm 60,2 / 68,1 inch |

250 m3h 8828 ft3h |

| LF 40.25 | 4000 x 2500 mm 157,5 x 98,4 inch |

4050 x 2550 mm 159,4 x 100,4 inch |

900 / 1200 mm 35,4 / 47,2 inch |

1530 / 1730 mm 60,2 / 68,1 inch |

250 m3h 8828 ft3h |

TECHNICAL DATA COMMON TO ALL MACHINES

| HEATING ELEMENTS | HEATING MOVEMENT | TABLE MOVEMENT | LOADING/UNLOADING |

| Standard: ceramic/hr ceramic On request: quartz/halogen |

Pneumatic | Servomotors | Manual (optional sheet loader) |